When we think about quality, we generally think of it in the most abstract sense. A quality team… assures that everything is of the highest… quality. Throw other abstract concepts like “regulatory compliance” “assurance program” and “supply chain management” and we can easily nod our heads and say “yeah that’s what quality does.” We might even have an in house quality team of experts who work right across from us. We see them come in everyday and work hard at what they do, and despite the nuances, at a surface level we know that quality is important. But if someone were to ask us to really break it down, it’s probable that we would struggle at explaining all the steps to them. A big reason is because it is a complex role with folds, layers and sub-pockets most people don’t even know about.

In the frozen industry, the role of quality has vastly expanded within the last eight years. In the U.S, an effort to reduce food-borne illnesses drove the creation and enactment of the Food Safety Modernization Act (FSMA). Similar food safety compliance programs exist today all over the world on every continent. At a local scale, FSMA changed the landscape of the food manufacturing industry, and hit farms, facilities, suppliers and everyone in between hard with inspections, compliance dates and mandatory preventive controls. Some have since referred to this change as the driver for Industry 4.0, the next stage of the frozen food industry, where regulated compliance policies have replaced human actors in shaping the food industry.[1] How Brecon “Leaned In”

Since the implementation of FSMA, we have seen big moves towards best practices in food safety as well as a collective call for overall traceability within the supply chain. The phrase “Farm to Fork” continues to snowball with meaning, even so far as inspiring new phrases in adjacent industries like “Dock to Dish.” Talks about block-chain are prevalent and consistent, and working with accredited players is more important than ever.

Adopting a business model that complied with these new regulations was and continues to be a formidable task. The quality revolution brought with it a confusing mish mash of audits, regulatory authorities and screening programs. As an intermediary, Brecon was not only tasked with dealing with these changes internally, but for its partners as well. The question transformed from “how do we support ourselves” to “how do we support ourselves as well as our extended global partners?” Within this climate of confusing changes and updated policies, it could have been very easy to throw our hands up and scream “I don’t get it.” Instead, Brecon rolled up its sleeves and embraced the opportunity for growth and expansion.

As a global merchant and international trader, our focus is not solely on American markets. We coordinate imports and exports to and from regions on all six continents. But it was undeniable that FSMA had a global impact, and it was its creation in part that cradled the birth of the MAP™ program, and inspired a business plan that put quality and food safety in the driver’s seat. In house quality not only became a feature of the Brecon team, but a backbone.

Quality At Every Stage

Quality is present at every step of the process. In fact, our quality agents begin working even before a sale is finalized. Any potential supplier (or lead) needs to satisfy a series of pre-qualifications. Brecon is prudent about who they partner with, so as to assure optimal product for their customers. The pre-qualification process entails a fair amount of research conducted by the quality person. They will first assure that the supplier and facility are GFSI certified, meaning approved by the Global Food Safety Initiative. THE GFSI recognizes select audit programs; if for some reason a supplier fails to have any of these programs in place, they are unable to move to the next round of auditing.

Next, the quality agent will verify that the facility has a strong regulatory compliance with respect to microbes (germs) and pathogens. They will look at factors like maximum pesticide residue limits, as well as overall traceability. Can the facility properly identify which product comes from which farm?

Other factors include ethical appraisals, business climate, sustainability systems, food defense plans, good agricultural and environmental controls and other relevant market considerations. If a supplier meets this criteria, they can then move on to be MAP™ assessed.

Understanding MAP

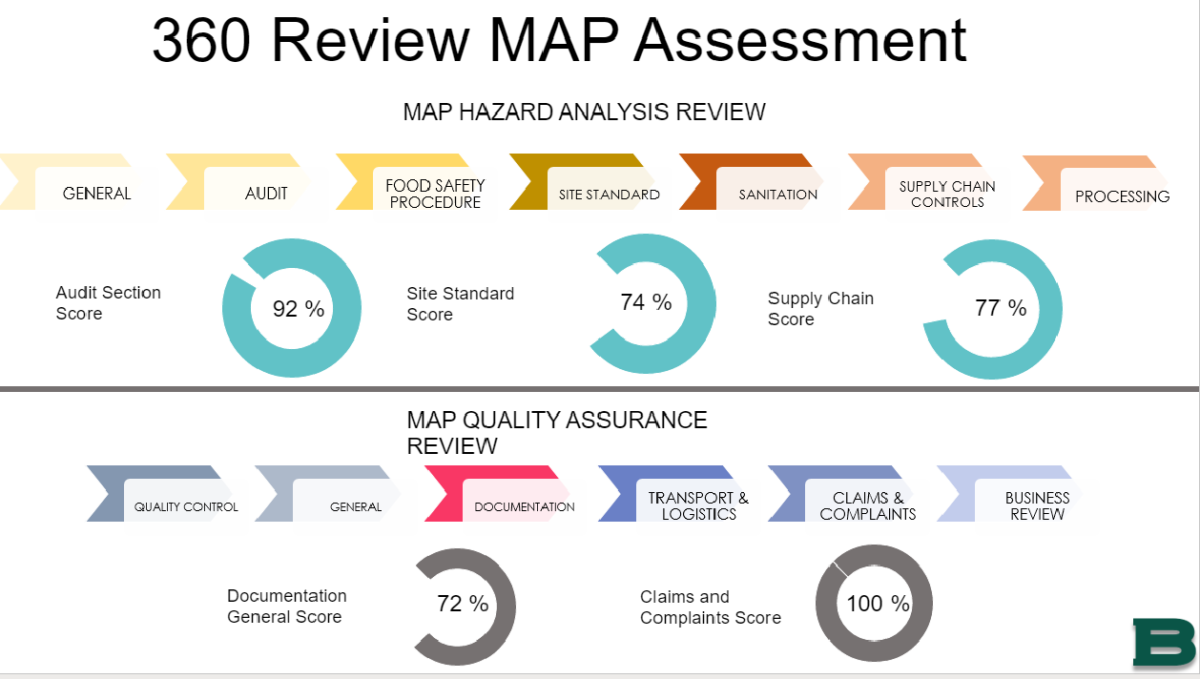

The Brecon MAP™ program is best described as a 360 degree desk audit, which includes elevated factory visits onsite to assure that Good Manufacturing Practices (GMP) are updated and in place. It is a comprehensive assessment which thoroughly analyzes and reviews over a dozen components of the supply chain and scores each category accordingly. The quality team is then able to average an overall score for that manufacturer, which they can later use to pair with customer specifications. Many people don’t realize that this is a lengthy process. Each category requires dedicated time and effort, as well as various kinds of documentation.

Our quality agents are able to provide MAP™ participants with a clear picture of what should be improved on, and beyond that help them close these supply chain gaps. In doing so, suppliers and customers can open doors to new markets, and find stronger synergy with one another.

Quality then follows the sale until the product has arrived at it’s intended destination.This includes elements like labeling and temperatures during travel. In the U.S specifically, Brecon acts as your importer of record (CTPAT certified), relieving our partners of any risks associated with importing outside goods. The quality team is equally responsible for investigating and mediating any claims between customers and suppliers.

Partnering with Brecon means partnering with peace of mind. Not only can you be confident knowing you’re working with a reputable team of experts who have evolved alongside the frozen industry, but Brecon also serves as your personalized gateway to new markets, quality products and facilitated convenience along the supply chain.